Extruded polystyrene Insulation made from extruded polystyrene XPS can be an important part of a construction IAQ management plan which is often part of green-building rating programs. Polystyrene extruded sheet includes foam for packaging and buoyancy or flotation.

Upon heating during expansion resulting granules size 05-15mm which are then used as a heat insulating dikes as fillings foam polystyrene Concrete.

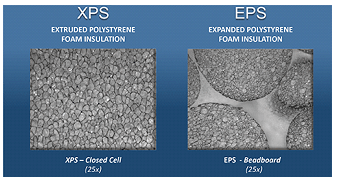

Expanded vs extruded polystyrene green building. The key difference between expanded and extruded polystyrene is that we produce expanded polystyrene or EPS from solid beads of polystyrene while we produce extruded polystyrene or XPS from solid polystyrene crystals. XPS on the other hand is made using an extrusion process whereby polystyrene is mixed with additives and a blowing agent which is then melted together through a dye. Expanded polystyrene is a type of foam made from polystyrene.

Toward that end polystyrene insulation both extruded XPS and expanded EPS plays a key role in many energy-efficient green buildings. Many researches have analyzed the development of composite panels for building applications using rigid and soft cores with thermoset and thermoplastic face sheets. EPS manufacturing does use a small amount of pentane and EPS resin the final EPS product is about 96 air.

One method to insulate a building is by installing 50 to 152 mm 2 to 6 in of rigid foam insulation on the exterior side of the wall framing. Expanded polystyrene EPS - density 30 kgm³ 815320025 A. The main difference between these two materials lies in their density.

Extruded Polystyrene XPS EPS Differentiators It must also be noted that stated R-values of insulations products vary under different conditions and truly credible comparisons must take into consideration the specific brands of foam and specific test conditions. 20 BUILD JUNEJULY 2004 build right by Ian Cox-Smith BRANZ Building Physicist R igid polystyrene foam is available in two forms extruded XPS and expanded EPS. Extruded polystyrene XPS HFC blown density 35 kgm³.

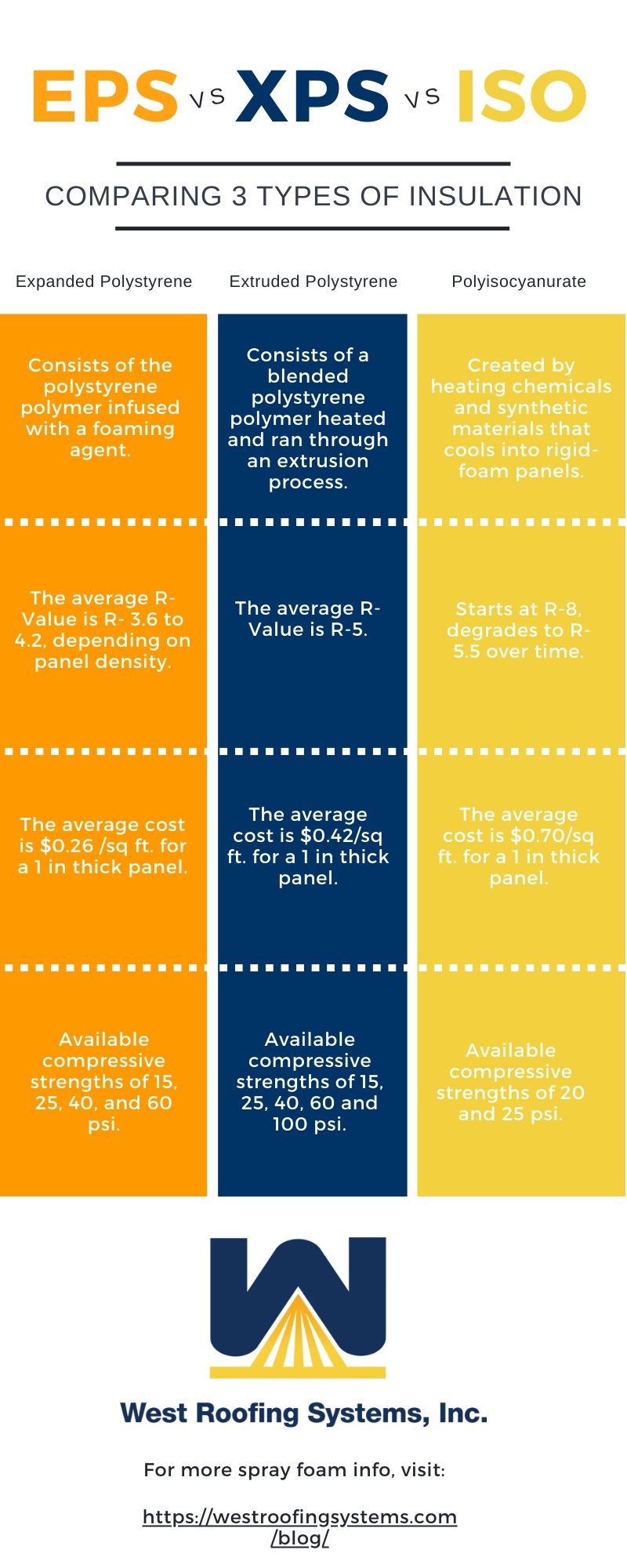

Most of the works here are completed with one or other forms of polystyrene or other Styro varients. When building or renovating a high-performance building envelope there are really three main kinds of rigid foam panels you are going to have to choose from - Polyisocyanurate known as Polyiso PIR Extruded Polystyrene XPS - often called Styrofoam - and Expanded Polystyrene. Hi Thank you for adding me to this professional community.

Two of the most frequently installed types of rigid foam insulation are expanded and extruded polystyrene EPS and XPS. The extruded form is usually coloured and has a uniform texture while expanded polystyrene the most common is usually white and has a clearly visible bead structure. Expanded polystyrene and green concepts.

The Difference between Expanded Polystyrene and Extruded Polystyrene. What Is The Difference Between Expanded Polystyrene Eps And Extruded Polystyrene Xps. Polystyrene panels are primarily used to insulate houses but they can also be used in the creation of sets for artistic projects for example.

Currently I am working here in the Middle East in a construction company. It is a lightweight rigid and closed cell insulation. Integritemp Plastilite announced a patent-pending ReFoam an expanded polystyrene EPS product that is oxo-biodegradable and recyclable.

Insulation is a critical component of our buildings and providing high R-values must be a high priority in creating green buildings of nearly all types and sizes. Hi I am expecting experts advice on the Green side of expanded polystyrene EPS building materials. We need a realistic solution today.

Expanded polystyrene EPS - density 40 kgm³ 1315320001 A. Our elation lasted for about 2 seconds until we saw the judges comments which were very critical of our use of Portland cement the key ingredient to concrete and expanded polystyrene EPS as insulation for our building materials. 59 CSIP is implemented as.

EPS should not be confused with extruded polystyrene XPS which is produced using CFCs. The next step and most common is processing in specific products without the use of additional binders. The material is designed to reduce the moisture infiltration and condensation.

Polystyrene extruded boardstock and billet includes insulation for roofing walls floors and pipes Perhaps some insulation manufacturers will start differentiating their XPS by transitioning sooner. 60-65 Compared to CSIP constructed using typical sandwich method the developed CSIP boosts better strength and creep resistance due to 125 times more face sheets-to-core moduli ratio. Additionally extruded polystyrene generates neither dust nor airborne.

Last time I mentioned that we BuildFast were selected as finalists in the California Clean Tech Open Green Building Category. Jon Ehly President and CEO said Weve been in RD mode with ReFoam for the last few years working to create a material that will give our customers all the familiar benefits of EPS but with added environmentally friendly end-of-life options. Since the mid 1950s expanded polystyrene has not been produced with CFCs chlorofluorocarbons1.

Komentar

Posting Komentar